We use cookies to ensure your best experience. Find out more about our Cookie Policy and Privacy Policy.

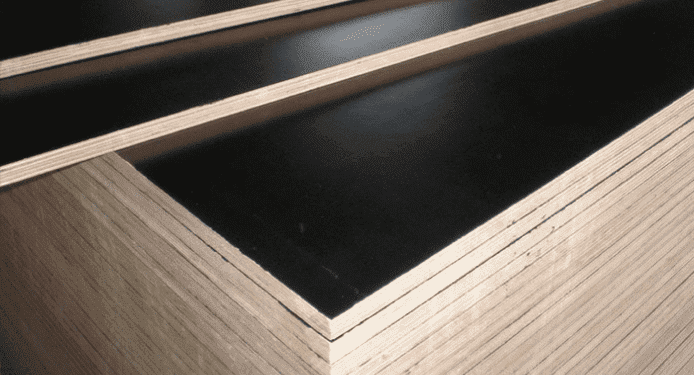

Raw material: Multilaminated pine.

Coating: 125 g/m2 phenolic film on both sides.

Bonding: Waterproof WBP phenolic resin.

Finishing: Painted and sealed on the sides.

Use: Internally or externally in the assembly for the construction of concrete forms of beams, slabs, pillars and foundations.

Reusability: 20 times or more (in strict compliance with usage and storage regulations).

| Thickness | 18 mm |

| Width | 1220 and 1250 mm |

| Length | 2440 and 2500 mm |

| Moisture (%) | 10.9 ( +/- 0.3 ) |

| Density (kg/m3) | 569 ( +/- 29 ) |

| MOE - Modulus of Elasticity in static bending ( N/mm2 ) ( MPa ) | Longitudinal 5960 ( +/- 490 ) / Transversal 5580 ( +/- 370 ) |

| MOR - Modulus of Rupture in static flexure ( N/mm2 ) ( MPa ) | Longitudinal 52.3 ( +/- 5.6 ) / Transversal 39.2 ( +/- 6.1 ) |

| Shear bond strength with 24h immersion in water | 1.45 % (+- 0.36) |

| Shear bond strength in immersion with boiling water | 1.48 % (+- 0.50) |

| Standard Shear Deviation | 0.32 |

| Swelling | 3.4% |

| Water Absorption | 51.6% |

| Formaldehyde Release, EN 13986/04 Standard | Class E1 (Less than or equal to 3.5 mg/m2h) |

| Taber Abrasion Resistance | 0.28 mm thickness reduction with 95% wear on the test specimen |

| Thickness | 18.3 +-0.1 mm |

| Width | 1220 mm |

| Length | 2440 mm |

| Density (kg/m3) | 0.61 +- 0.01 |

| Square | 2728 mm |

| Straightness | 0.5 |

| MOE - Module of Static flexural elasticity | Longitudinal 5836(Mpa) / Transverse 4494(Mpa) |

| MOR - Static flexural modulus of rupture | Longitudinal 44.9(Mpa) / Transverse 37.1(Mpa) |

| Shear Tension (5KN AME universal testing machine) | 1.27 +- 0.01 |

| Shear % Fibers (5KN AME universal testing machine) | 51 |

| Shear Deviation Default | 0.19 and 30 |

| Thickness | 14.7 +-0.1 mm |

| Width | 1220 mm |

| Length | 2440 mm |

| Density (kg/m3) | 0.63 +- 0.01 |

| Square | 2728 mm |

| Straightness | 0.5 |

| MOE - Module of Static flexural elasticity | Longitudinal 4139(Mpa) / Transverse 3505(Mpa) |

| MOR - Static flexural modulus of rupture | Longitudinal 40.6(Mpa) / Transverse 38.4(Mpa) |

| Shear Tension (5KN AME universal testing machine) | 1.11 +- 0.02 |

| Shear % Fibers (5KN AME universal testing machine) | 75 |

| Shear Deviation Default | 0.32 |

Raw material: Multi-laminated pine plywood.

Bonding: Waterproof WBP phenolic resin.

Use: Internal or external in the assembly of concrete forms, partitions, walls, packaging, furniture and upholstery.

| Thickness | 6, 9, 12, 15, 18 and 21 mm |

| Width | 1220 and 1250 mm |

| Length | 2440 and 2500 mm |

| Density (kg/m3) | 579 (+/- 20) |

| MOE - Modulus of Elasticity (N/mm2) (MPa) | Longitudinal 5130 (+/- 1240) / Transverse 4780 (+/- 600) |

| MOR - Rupture Modulus (N/mm2) (MPa) | Longitudinal 36.6 (+/- 8.0) / Transverse 48.8 (+/-5.5) |

| Shear bonding strength after 24 hours of immersion in water | 1.29 % (+/- 0.33) |

| Shear bonding strength when immersed in boiling water | 1.42 % (+/- 0.44) |

| Swelling | 6.5% |

| Water absorption | 51.3% |

| Released formaldehyde, standard EN 13986/04 | Class E1 (Less than or equal to 3.5 mg/m2h) |

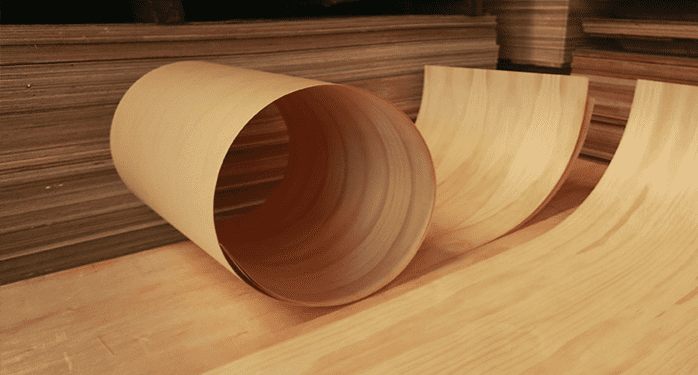

Pine veneers produced on a mechanical lathe.

Thickness: from 1.5 to 4.0 mm

Dimensions: 1300 mm and 1300 mm long

or 1300 mm and 2600 mm long.

Humidity and classification: According to customer specifications.

OUR PRODUCTS